電氣書籍 電氣控制從入門到精通電氣控制與plc應(yīng)用技術(shù)識圖電力電子元器件傳感器變頻器觸摸屏電氣實物接線自動化電工基礎(chǔ)自學(xué)教材

- 價 格: ¥ 209

- 今日價格: 有特價請聯(lián)系

- 商品庫存: 30 件

- 品牌:

- 貨號:61d19dc1196c

- 立刻聯(lián)系購買聯(lián)系商家

- 產(chǎn)品名稱:電氣控制從入門到精通

- 書名:電氣控制從入門到精通

- 作者:無

- 定價:99.00元

- 書名:電氣控制從入門到精通

- 開本:16開

- 是否是套裝:否

- 出版社名稱:化學(xué)工業(yè)出版社

書名:電氣控制從入門到精通

定價:99.(咨詢特價)

作者:劉振全

出版社:化學(xué)工業(yè)出版社

ISBN(咨詢特價)

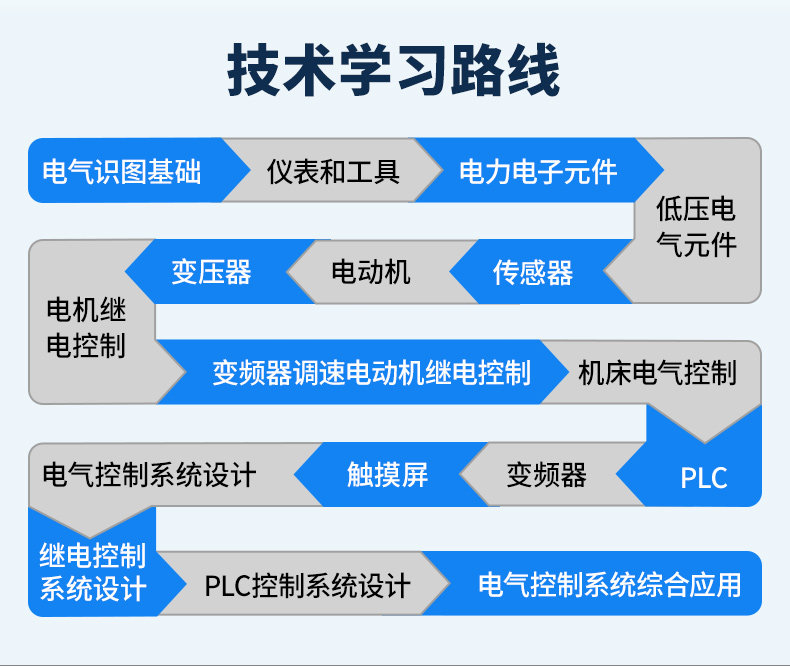

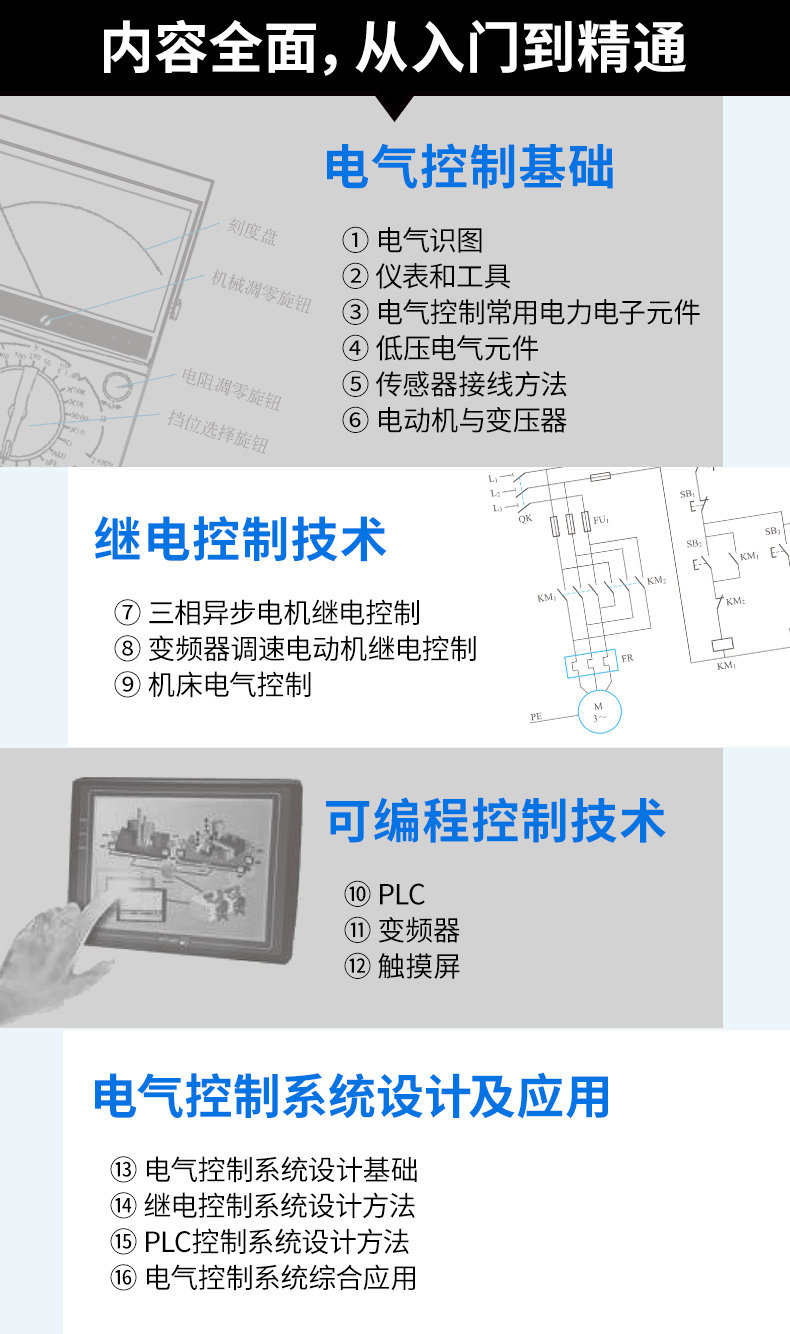

本書圖文并茂、由淺入深、案例豐富、例說應(yīng)用,為讀者搭建一條循序漸進學(xué)習(xí)電氣控 制技術(shù)的路線:電氣識圖基礎(chǔ)—儀表和工具—電力電子件—低壓電氣件—傳感器及其接 線方法—電動機與變癢—電機繼電控制—變頻器調(diào)速電動機繼電控制—機床電氣控制—PLC—變頻器—觸摸屏—電氣控制系統(tǒng)設(shè)計—繼電控制系統(tǒng)設(shè)計方法—PLC控制系統(tǒng)設(shè)計方法—電氣控制系統(tǒng)綜合應(yīng)用。

本書可作為廣大電氣工程技術(shù)人員學(xué)習(xí)電氣控制技術(shù)的參考用書,也可作為高等院校、職 業(yè)院校自動化類、電氣類、機電一體化、電子信息類等相關(guān)專業(yè)的電氣控制技術(shù)教學(xué)或參考用書。

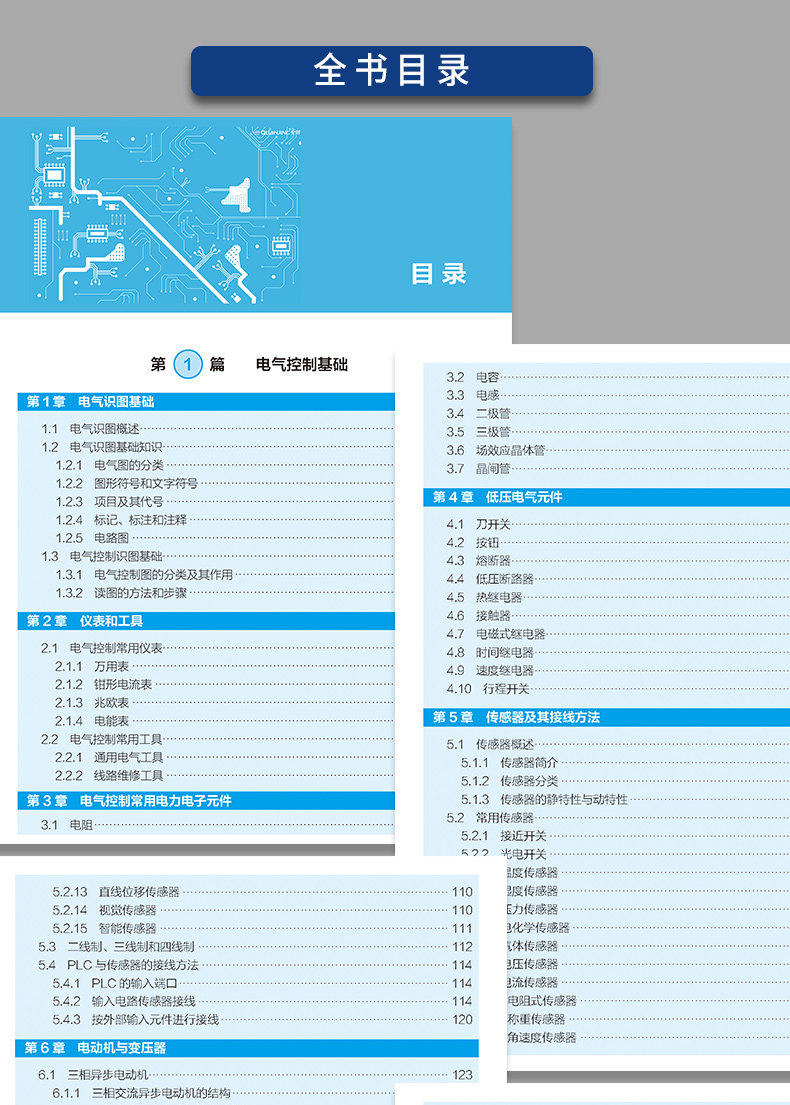

第1篇 電氣控制基礎(chǔ)

第1 章 電氣識圖基礎(chǔ)

1.1電氣識圖概述····························2

1.2電氣識圖基礎(chǔ)知識························4

1.2.1電氣圖的分類·································4

1.2.2圖形符號和文字符號····························7

1.2.3項目及其代號·······························15

1.2.4標記、標注和注釋···········19

1.2.5電路圖·······································25

1.3電氣控制識圖基礎(chǔ)·······························29

1.3.1 電氣控制圖的分類及其作用

1.3.2 讀圖的方法和步驟

第 2 章 儀表和工具

2.1 電氣控制常用儀表···················32

2.1.1 萬用表································32

2.1.2 鉗形電流表·························39

2.1.3 兆歐表································43

2.1.4 電能表·······························47

2.2 電氣控制常用工具···························49

2.2.1 通用電氣工具·······················49

2.2.2 線路維修工具·····························52

第 3 章 電氣控制常用電力電子件

3.1 電阻·····

3.2電容·······························61

3.3電感·························65

3.4二極管······································69

3.5三極管································75

3.6場效應(yīng)晶體管····················78

3.7晶閘管··

第 4 章 低壓電氣件

4.1 刀開關(guān)································84

4.2按鈕·······································85

4.3熔斷器······································86

4.4低壓斷路器·····························87

4.5熱繼電器·····································88

4.6接觸器···························89

4.7電磁式繼電器····················90

4.8時間繼電器································92

4.9速度繼電器···························93

4.10行程開關(guān)······························94

第 5 章 傳感器及其接線方法

5.1 傳感器概述·································96

5.1.1傳感器簡介································96

5.1.2傳感器分類·······································97

5.1.3傳感器的靜特性與動特性···························98

5.2常用傳感器································99

5.2.1接近開關(guān)·······························99

5.2.2光電開關(guān)·····························100

5.2.3溫度傳感器·····················101

5.2.4濕度傳感器························102

5.2.5壓力傳感器································103

5.2.6電化學(xué)傳感器····························104

5.2.7氣體傳感器···································105

5.2.8電壓傳感器·····································

5.2.9電流傳感器································106

5.2.10電阻式傳感器····································107

5.2.11稱重傳感器··························108

5.2.12角速度傳感器·

5.2.13直線位移傳感器·····························110

5.2.14視覺傳感器····························110

5.2.15智能傳感器·································111

5.3 二線制、三線制和四線制·························112

5.4 PLC 與傳感器的接線方法······························114

5.4.1PLC的輸入端口····································114

5.4.2輸入電路傳感器接線·························114

5.4.3按外部輸入件進行接線········

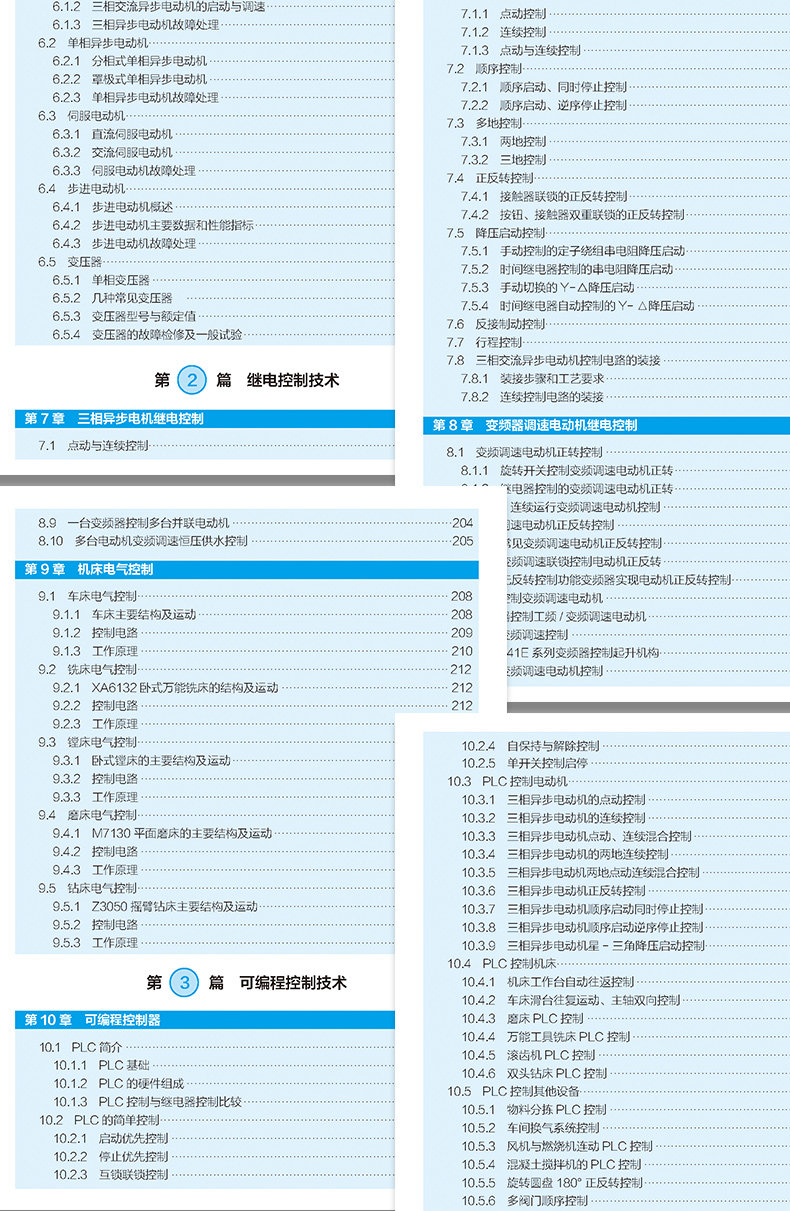

第 6 章 電動機與變癢

6.1 三相異步電動機·························123

6.1.1 三相交流異步電動機的結(jié)構(gòu)··············123

6.1.2 三相交流異步電動機的啟動與調(diào)速·············126

6.1.3 三相異步電動機故障處理·····················130

6.2單相異步電動機··································134

6.2.1 分相式單相異步電動機·············134

6.2.2罩極式單相異步電動機·····························136

6.2.3 單相異步電動機故障處理····················136

6.3伺服電動機·····························138

6.3.1 直流伺服電動機································138

6.3.2 交流伺服電動機·····························139

6.3.3伺服電動機故障處理··············140

6.4步進電動機······································144

6.4.1 步進電動機概述··································144

6.4.2步進電動機主要數(shù)據(jù)和性能指標·····················146

6.4.3步進電動機故障處理····················147

6.5變癢··········································150

6.5.1 單相變癢·····································150

6.5.2幾種常見變癢······························153

6.5.3 變癢型號與額定值···················

6.5.4 變癢的故障檢修及一般試驗·

第2篇 繼電控制技術(shù)

第 7 章 三相異步電機繼電控制

7.1 點動與連續(xù)控制············

7.1.1 點動控制·························162

7.1.2 連續(xù)控制·······································163

7.1.3 點動與連續(xù)控制···························164

7.2順序控制································165

7.2.1 順序啟動、同時停止控制··························166

7.2.2 順序啟動、逆序停止控制······················167

7.3多地控制·····························168

7.3.1 兩地控制·····························168

7.3.2 三地控制···············169

7.4正反轉(zhuǎn)控制···························170

7.4.1 接觸器聯(lián)鎖的正反轉(zhuǎn)控制··························170

7.4.2 按鈕、接觸器雙重聯(lián)鎖的正反轉(zhuǎn)控制·············171

7.5降陽動控制······························173

7.5.1 手動控制的定子繞組串電阻降陽動··········173

7.5.2 時間繼電器控制的串電阻降陽動·················174

7.5.3 手動切換的Y-△降陽動·······················175

7.5.4 時間繼電器自動控制的Y- △降陽動···················177

7.6反接制動控制····························179

7.7行程控制··································

7.8三相交流異步電動機控制電路的裝接·············182

7.8.1 裝接步驟和工藝要求···················182

7.8.2 連續(xù)控制電路的裝接···

第 8 章 變頻器調(diào)速電動機繼電控制

8.1 變頻調(diào)速電動機正轉(zhuǎn)控制············

8.1.1旋轉(zhuǎn)開關(guān)控制變頻調(diào)速電動機正轉(zhuǎn)·······················187

8.1.2繼電器控制的變頻調(diào)速電動機正轉(zhuǎn)···············188

8.2點動、連續(xù)運行變頻調(diào)速電動機控制···············190

8.3變頻調(diào)速電動機正反轉(zhuǎn)控制····························191

8.3.1常見變頻調(diào)速電動機正反轉(zhuǎn)控制··························191

8.3.2變頻調(diào)速聯(lián)鎖控制電動機正反轉(zhuǎn)·····················194

8.3.3無反轉(zhuǎn)控制功能變頻器實現(xiàn)電動機正反轉(zhuǎn)控制··················195

8.4兩地控制變頻調(diào)速電動機·········196

8.5繼電器控制工頻/變頻調(diào)速電動機······························197

8.6風(fēng)機變頻調(diào)速控制···························199

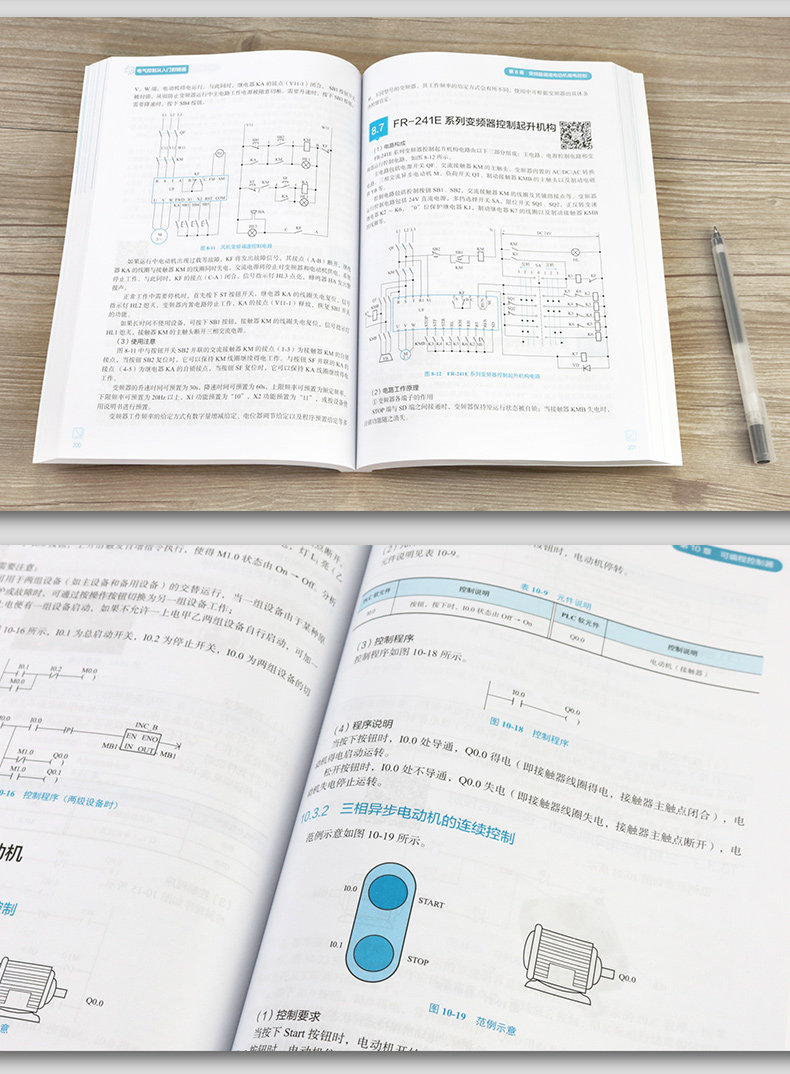

8.7FR-241E系列變頻器控制起升機構(gòu)

8.8變極變頻調(diào)速電動機控制

8.9一臺變頻器控制多臺并聯(lián)電動機·················204

8.10多臺電動機變頻調(diào)速恒壓供水控制···································205

第 9 章 機床電氣控制

9.1 車床電氣控制·····································208

9.1.1車床主要結(jié)構(gòu)及運動·······················208

9.1.2控制電路············································209

9.1.3工作原理·····································210

9.2銑床電氣控制······························212

9.2.1XA6132臥式很多能銑床的結(jié)構(gòu)及運動··················212

9.2.2控制電路······························212

9.2.3工作原理····························214

9.3鏜床電氣控制···························219

9.3.1臥式鏜床的主要結(jié)構(gòu)及運動·········220

9.3.2控制電路······················220

9.3.3工作原理······················222

9.4磨床電氣控制·························225

9.4.1M7130平面磨床的主要結(jié)構(gòu)及運動·················225

9.4.2控制電路·························227

9.4.3工作原理··································228

9.5鉆床電氣控制··················

9.5.1Z3050搖臂鉆床主要結(jié)構(gòu)及運動····230

9.5.2控制電路·················230

9.5.3工作原理

第3篇 可編程控制技術(shù)

第 10 章 可編程控制器

10.1 PLC 簡介············236

10.1.1 PLC 基礎(chǔ)··················236

10.1.2 PLC 的硬件組成···············237

10.1.3 PLC 控制與繼電器控制比較····················239

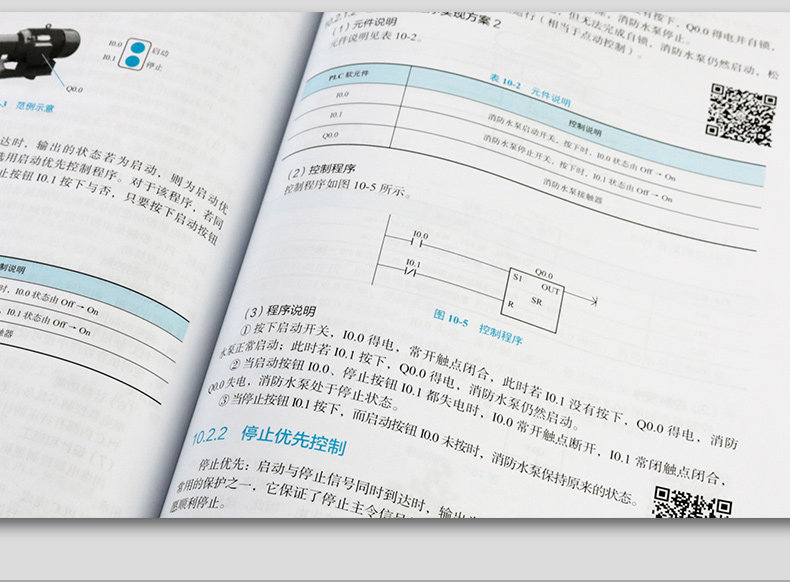

10.2PLC的簡單控制································240

10.2.1 啟動優(yōu)先控制··························240

10.2.2 停止優(yōu)先控制·························241

10.2.3互鎖聯(lián)鎖控制········

10.2.4自保持與解除控制··············245

10.2.5單開關(guān)控制啟停·······························247

10.3PLC控制電動機································248

10.3.1 三相異步電動機的點動控制····················248

10.3.2 三相異步電動機的連續(xù)控制····················249

10.3.3 三相異步電動機點動、連續(xù)混合控制·········250

10.3.4 三相異步電動機的兩地連續(xù)控制··················253

10.3.5 三相異步電動機兩地點動連續(xù)混合控制·················254

10.3.6 三相異步電動機正反轉(zhuǎn)控制··························256

10.3.7 三相異步電動機順序啟動同時停止控制················257

10.3.8 三相異步電動機順序啟動逆序停止控制··258

10.3.9 三相異步電動機星-三角降陽動控制··············260

10.4PLC控制機床·························261

10.4.1 機床工作臺自動往返控制·······················261

10.4.2 車床滑臺往復(fù)運動、主軸雙向控制···············262

10.4.3 磨床PLC控制················264

10.4.4 很多能工具銑床PLC控制··············266

10.4.5 滾齒機PLC控制······················268

10.4.6 雙頭鉆床PLC控制···················269

10.5PLC控制其他設(shè)備························271

10.5.1 物料分揀PLC控制··········271

10.5.2 車間換氣系統(tǒng)控制··························273

10.5.3 風(fēng)機與燃燒機連動PLC控制·········274

10.5.4 混凝土攪拌機的PLC控制···············275

10.5.5 旋轉(zhuǎn)圓盤180°正反轉(zhuǎn)控制·····················277

10.5.6 多閥門順序控制························278

10.5.7 物流檢測控制·······················279

10.5.8 模具成型控制··································281

10.5.9 伺服電機位置控制····································282

10.5.10 步進電機位置閉環(huán)控制····························288

第 11 章 變頻器

11.1變頻器概述

11.1.1變頻器的安裝··················293

11.1.2變頻器的接線···························294

11.1.3變頻器的參數(shù)設(shè)定························296

11.2變頻器選型技巧及分類····

11.2.1變頻器所驅(qū)動的負載特性·················300

11.2.2不同電機對變頻器選型的影響·······301

11.2.3變頻器周邊器件的選擇························301

11.2.4變頻器的分類及應(yīng)用··················305

11.3變頻器故障維修···································308

11.3.1變頻器的故障類型························308

11.3.2變頻器維修檢測常用方法···················310

11.4PLC與變頻器控制電動機實現(xiàn)的15段速控制系統(tǒng)······················311

第 12 章 觸摸屏

12.1觸摸屏概述·······························316

12.1.1觸摸屏的概念和功能··············316

12.1.2HMI軟件的安裝··························317

12.1.3HMI與控制器的通信································317

12.2觸摸屏的使用·······················319

12.2.1HMI工程文件的建立···················319

12.2.2HMI窗口的建立與設(shè)置······················319

12.2.3HMI按鈕與指示燈的設(shè)計···············320

12.2.4HMI數(shù)據(jù)顯示的設(shè)計··························321

12.2.5HMI時間顯示·································321

12.2.6HMI的UI設(shè)計·························321

12.2.7HMI的事件登錄及報警設(shè)計·················322

12.2.8HMI的數(shù)據(jù)采集與歷史趨勢圖設(shè)計···················323

12.2.9HMI配方的應(yīng)用·························324

12.2.10HMI用戶操作權(quán)限設(shè)置·························325

12.3觸摸屏和PLC的應(yīng)用····················327

第4篇 電氣控制系統(tǒng)設(shè)計及應(yīng)用

第 13 章 電氣控制系統(tǒng)設(shè)計基礎(chǔ)

13.1電氣控制設(shè)計的原則和內(nèi)容·······338

13.1.1電氣控制設(shè)計的一般原則·····················

13.1.2電氣控制設(shè)計的基本任務(wù)、內(nèi)容·················338

13.1.3電氣控制系統(tǒng)設(shè)計的一般步驟··························339

13.2電氣控制原理電路設(shè)計的方法··············340

13.2.1基本設(shè)計方法···

13.2.2原理圖設(shè)計的一般要求·························341

13.3電氣控制線路設(shè)計的主要參數(shù)計算·······················344

13.3.1異步電動機啟動、制動電阻的計算·········344

13.3.2籠型異步電動機能耗制動參數(shù)計算··········345

13.3.3控制變癢的選用··················346

13.3.4接觸器的選用··················346

13.3.5電磁式控制繼電器的選用···················348

13.3.6熱繼電器的選用···························349

13.3.7熔斷器選擇··································349

13.3.8其他控制電器的選用···························350

13.4電氣控制裝置的工藝設(shè)計··············350

13.4.1電氣設(shè)備的總體布置設(shè)計·············351

13.4.2繪制電器件布置圖···················351

13.4.3繪制電氣控制裝置的接線圖··············351

13.4.4電控柜和非標準零件圖的設(shè)計···················352

13.4.5清單匯總·················352

13.4.6編寫設(shè)計說明書和使用說明書··················352

第 14 章 繼電控制系統(tǒng)設(shè)計方法

14.1繼電控制線路設(shè)計法························353

14.1.1電氣控制線路的一般設(shè)計法··············353

14.1.2電氣控制線路的邏輯設(shè)計法·····················356

14.2繼電控制電路從原理圖到接線圖的轉(zhuǎn)換方法··················358

第 15 章PLC控制系統(tǒng)設(shè)計方法

15.1PLC應(yīng)用系統(tǒng)設(shè)計的一般步驟····················361

15.1.1控制系統(tǒng)的設(shè)計內(nèi)容··················361

15.1.2設(shè)計步驟·························361

15.2梯形圖經(jīng)驗設(shè)計法····························362

15.2.1經(jīng)驗設(shè)計法簡介·················362

15.2.2經(jīng)驗設(shè)計法舉例······················363

15.3梯形圖順序控制設(shè)計法··············365

15.3.1順序控制設(shè)計法簡介

15.4.1模擬量控制簡介························378

15.4.2模擬量輸入輸出混合模塊···················379

15.4.3模擬量擴展模塊的尋址··········································383

15.4.4模擬量值和A/D轉(zhuǎn)換值的轉(zhuǎn)換····················383

15.4.5模擬量編程示意······················384

第 16 章 電氣控制系統(tǒng)綜合應(yīng)用

16.1 觸摸屏、變頻器和PLC的水位控制系統(tǒng)············385

16.2具有多種工作方式的機械手控制系統(tǒng)·······391

16.2.1機械手控制系統(tǒng)簡介·······················391

16.2.2使用啟保停電路編程法編寫系統(tǒng)程序···················393

16.2.3使用置位復(fù)位指令法編寫系統(tǒng)程序··········

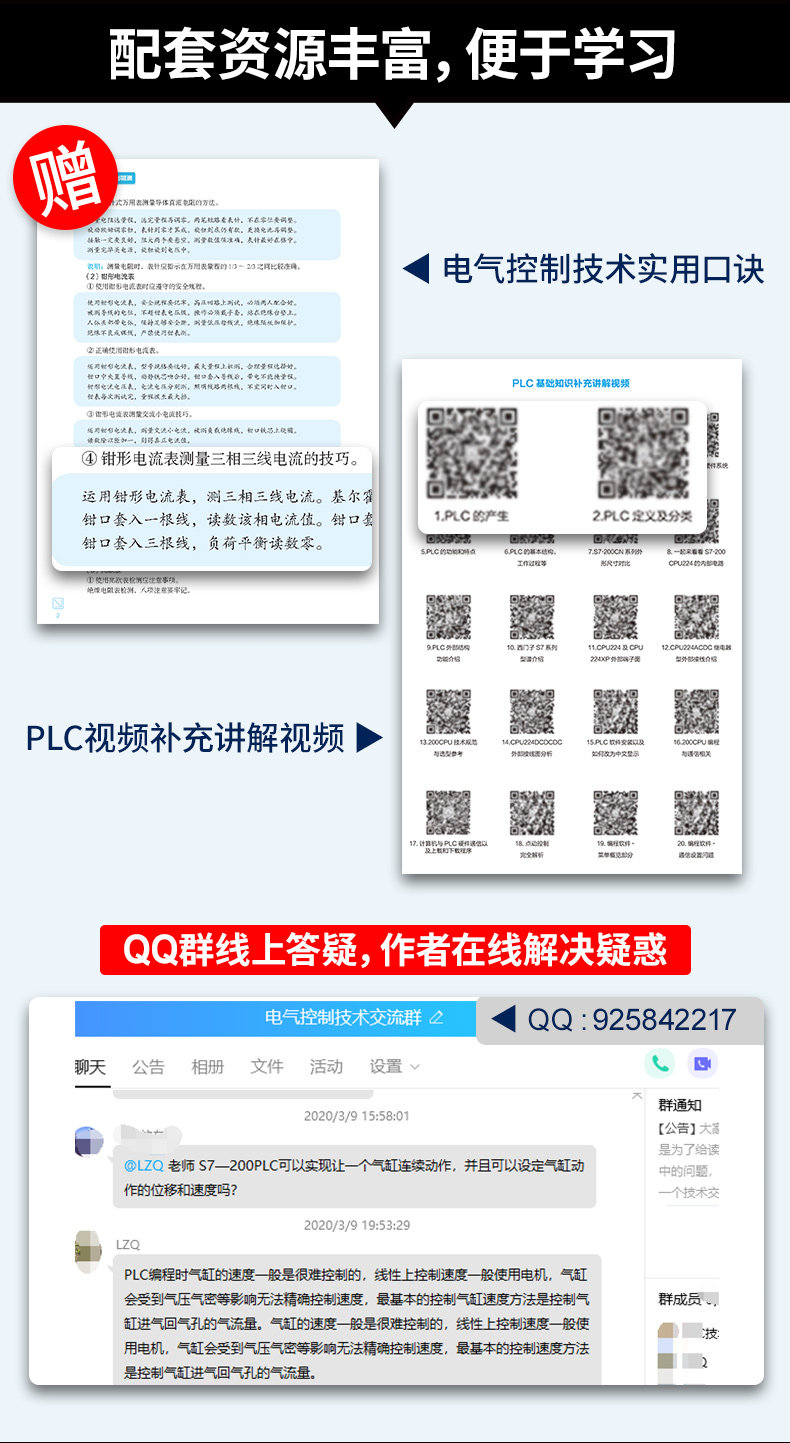

PLC 基礎(chǔ)知識補充講解視頻

二維碼索引

參考文獻

-

最近銷售:1357 掌柜:¥209 元

-

最近銷售:0 掌柜:¥255 元

-

最近銷售:36 掌柜:¥14249 元

-

最近銷售:1000 掌柜:¥59 元

-

最近銷售:94 掌柜:¥102 元

-

最近銷售:0 掌柜:¥269 元

浙公網(wǎng)安備 33011002014637號

浙公網(wǎng)安備 33011002014637號